Click photo to see job details

Author Archives: Peggy

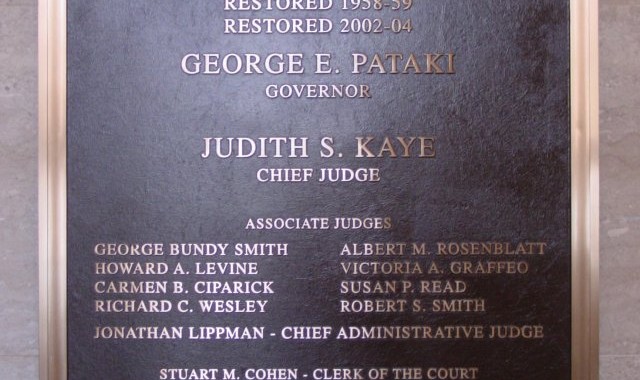

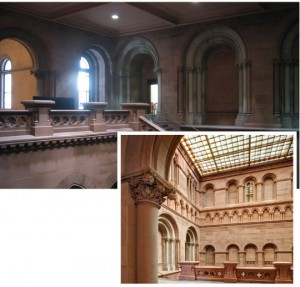

Decorative Copper Framework for the Historic Senate Staircase Laylight in the NYS Capitol

Click photo to see job details.

During WWII, the skylights in the NYS Capitol were painted black for safety reasons. These areas were eventually converted to office space. During a major roof renovation in the 2010 timeframe this skylight & laylight were revealed and brought back to their grandeur and flooding the stairway with natural light.

Historic Bronze Torchieres

Click photo to see job details

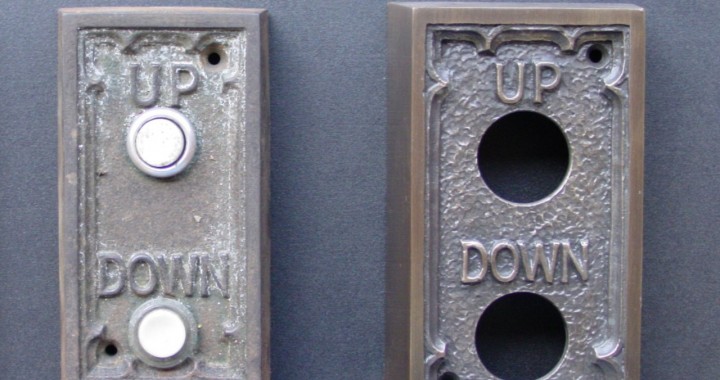

The original torchieres, which were natural gas powered, were melted down for the war effort. Since none existed to take patterns from, we reproduced them from historic photos and extremely detailed architects’ drawings from John G Waite and Associates.

Each torchiere is 14’ tall and is comprised of 70 components. Several processes were used in fabrication such as casting, metal spinning, lathe turning, machining, water jetting, welding, brazing, polishing, etc. We hand-carved approximately 20 different patterns and molds for both lost wax and sand cast components. The globes were custom made. All fixtures are UL approved.